Aerial Prospex developed an autonomous drone system that lives on your jobsite and delivers real-time visibility, without anyone needing to fly it. This system can fly on a schedule, on demand or seconds after a triggering event such as when motion is detected after hours.

and delivers real-time visibility, without anyone needing to fly it. This system can fly on a schedule, on demand or seconds after a triggering event such as when motion is detected after hours.

T he system’s drone docks are weatherproof charging stations that house a drone, charge its batteries, upload data to the cloud and enable repeatable, automated flight missions, all without human intervention. Once deployed on site, the dock connects to power and the internet runs fully off-grid thanks to the AP Dock Ops Trailer. From that moment on, your jobsite is covered from above.

he system’s drone docks are weatherproof charging stations that house a drone, charge its batteries, upload data to the cloud and enable repeatable, automated flight missions, all without human intervention. Once deployed on site, the dock connects to power and the internet runs fully off-grid thanks to the AP Dock Ops Trailer. From that moment on, your jobsite is covered from above.

Flights can be scheduled daily, weekly or in response to milestones, deliveries or change events. The data collected includes high-resolution progress photos, 2D site maps, 3D models and more. Contractors, superintendents and project stakeholders can monitor job progress, document changes and resolve disputes faster, without waiting on a survey crew or walking the site.

With drone docks, you get smarter awareness, fewer surprises and better decisions—every day.

HOW DRONE DOCKS ARE BEING USED

Drone docks are being deployed across residential, commercial and infrastructure projects to provide jobsite intelligence that is faster, more consistent and easier to access. Contractors are using this technology to fill critical visibility gaps without increasing labor or pulling teams off task.1

REAL-WORLD RESULTS: WHEN DOCUMENTATION PAYS OFF

REAL-WORLD RESULTS: WHEN DOCUMENTATION PAYS OFF

A recent hillside stabilization project quickly turned into a case study in how real-time documentation can make or break a job. The slope had partially collapsed, and the solution involved cutting back the hillside and rebuilding a solid foundation of fill.

The initial estimate for the site work was $250,000. But as soon as crews started stripping the stone off the pad, it became obvious: the volumes were way off. The stone base was deeper, the failure more extensive and the fix more complex than expected. Luckily, a drone dock had already been deployed on site.2

From Day 1, the dock was flying daily missions automatically capturing aerial imagery and calculating cut-and-fill quantities. Within the first week, the data made it clear that the site work was going to far exceed the original estimate. The contractor brought this to the owner’s attention immediately. The owner’s response? “Keep working—we’ll tell you when to stop.”

So they did.

Each day, the drone flew. The crews kept cutting, filling, placing and stockpiling. Quantities were tracked.

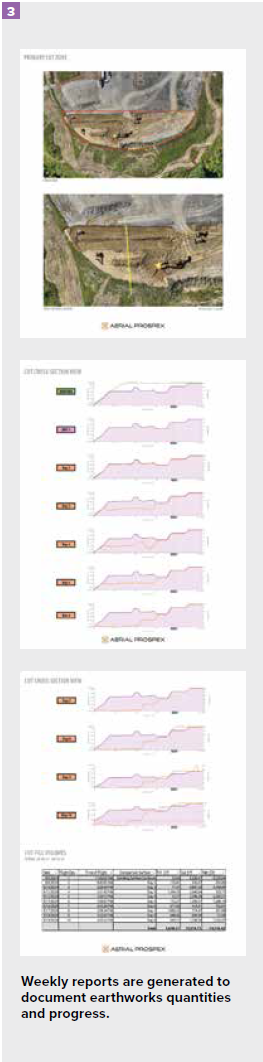

Progress photos were uploaded and shared with the owner and engineer. Every movement of earth was documented, and every dollar of progress was backed by hard data.3

Months passed. The site work bill had climbed to nearly half a million dollars, and the job was only three-quarters done. That’s when things got tense.

Despite having received weekly reports and visuals the entire time, higher-level decision-makers within the owner’s organization began to push back. They questioned the price, claimed they had only approved $250,000 and refused to release further payments.

But the contractor had what most don’t: daily evidence.

Every day was documented with geotagged photos, accurate drone- calculated volumes and a historical archive of progress reports. There was no ambiguity. Faced with that level of documentation, the owner had no choice but to honor the work completed and issue payment in full.

This level of tracking would have been nearly impossible using traditional methods. The site crews were in constant motion: cutting and filling, stockpiling and placing, often doing several things at once. Daily surveys would’ve been cost- prohibitive, and walking the site wouldn’t have captured enough detail. The drone dock, on the other hand, captured everything consistently, passively and without slowing the crew down.

In this case, the drone dock didn’t just provide visibility, it protected the contractor’s bottom line.

WHAT TO TAKE AWAY

Drone docks aren’t just flying cameras; they are jobsite tools that deliver consistent, automated, real-time visibility. Think of them as a daily survey crew, documentation specialist, site security and progress tracker rolled into one, but without adding labor or slowing down the field.

For contractors, this means fewer surprises, faster decisions and solid proof when it matters most. Whether you’re managing earthwork, tracking deliveries or protecting your margins, drone docks give you the eyes, data and documentation you need without anyone having to lift a finger.

And when it comes to cost, drone docks deliver significant value. While pricing depends on your region and the type of data delivered, flights from a drone dock typically cost 50% to 75% less per mission than hiring a drone pilot to do the same work manually.

This isn’t future tech. It’s field-proven, already working today and built to scale across your jobs.