Daniel Maha, Senior Project Manager, Worth & Co.

In 2019, Worth & Co. was tasked with providing mechanical, plumbing and lab gases for the Pennsylvania Biotechnology Center in Doylestown. The project was funded by a grant with a nonnegotiable end date, which created initial concerns about the timeline. The onset of the pandemic added further uncertainty as the construction site was still deemed essential. Despite these challenges, the team at Worth demonstrated remarkable resilience and adaptability.

PLANNING AND INNOVATION

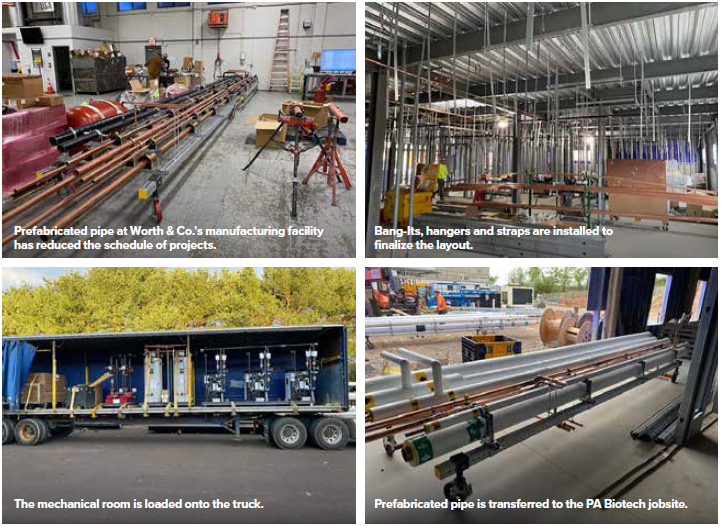

Prior to the COVID-19 pandemic, Worth, in collaboration with general contractor partner Norwood, began strategizing to tackle upcoming challenges. In the early meetings, Worth’s project team presented prefabrication concepts to the general contractor, the project design team and PA Biotech. This initiative ultimately allowed the project to be completed on schedule. The collaborative method not only streamlined the construction process but also enhanced overall efficiency.

PREFABRICATION AND BIM

PREFABRICATION AND BIM

Worth aimed to leverage its BIM and prefab capabilities to reduce the project schedule. Office meetings at PA Biotech became a platform for Worth to gain buy-in from trade partners, the design team and PA Biotech. Prefabrication efforts significantly cut down the timeline, which was crucial in addressing pandemic challenges. The use of BIM allowed for detailed visualization and coordination, minimizing conflicts and rework. This strategic approach not only accelerated the construction phase but also helped maintain quality standards.

VALUE ENGINEERING TO ENHANCE EFFICIENCY FOR ABOVE- AND BELOW-GROUND PIPING

The project began with value engineering aimed at improving fabrication and increasing efficiency. Worth and the design team modified the lab waste system from heavy-duty cast iron to ChemDrain CPVC, which enabled quicker installation. This change was beneficial because ChemDrain is glued, resulting in a lighter material that is easier to manage on site. This allowed Worth to fabricate a large section of the under- and above- ground piping, increasing installation efficiency on site.

To maximize efficiency in the above- ground piping, Worth prioritized coordination by collaborating closely with both the design team and various trades. It was crucial for their team to develop the optimal layout for all trades before construction began, which significantly enhanced efficiency. Worth’s team focused on installing Bang-Its and duct straps to finalize the layout. By proactively managing these elements, they ensured that hangers and materials could be installed without requiring additional layouts.

CHALLENGES AND SOLUTIONS

Installing lab gases presented a considerable challenge. Worth expedited the process by collaborating with Viega Press and its line of lab-approved fittings for nitrogen, vacuum and carbon dioxide. By utilizing Viega and its fittings, they were able to minimize the need for on-site brazing and the risk of exposure to hazardous fumes and potential fire hazards.

Limited hallway space posed another challenge. Worth’s team introduced a prefabricated rack system to house the mechanical components, which streamlined both the installation and future maintenance processes. Worth prefabricated the racks at its 75,000-square-foot prefabrication facility where they also tested and insulated all the components while on-site construction continued. This approach not only maximized the available space but also significantly accelerated the project timeline. As a result, workers were able to install an impressive 5,000 feet of piping in just four days, demonstrating both efficiency and precision in their work.

The mechanical room, often considered a difficult component because of space and time limitations, was prefabricated at Worth’s prefabrication facility. This strategy allowed the room to become operational in a matter of weeks rather than months.

ENHANCED OPERATIONAL CAPABILITIES

Without Worth’s innovative and unconventional thinking, the buy-in secured from trade partners and the design team and the dedicated efforts of the BIM department, prefab shop and field teams, completing this project within the designated time frame would have been nearly impossible due to its challenges and conditions. The lessons learned from this project have not only enhanced Worth’s operational capabilities but also gave them a new approach to tackling complex mechanical projects.

The commitment demonstrated throughout the PA Biotech project resulted in Worth returning to the Doylestown location to execute a small renovation. Their focus remains steadfast on fostering collaboration, embracing technological advancements and maintaining rigorous standards of safety and quality. More significantly, it has set the stage for new strategies and ideas to better serve all customers, including those in institutional, pharmaceutical, hospitality and general construction sectors. This positions Worth, a proud ABC member, as one of the country’s most innovative and productive merit shop mechanical and industrial firms.