Jeff Rogers, General Superintendent, Gaylor Electric

As the demand for high- performance data centers accelerates, the industry faces mounting pressure to deliver facilities faster, safer and with greater reliability. Traditional commissioning methods, particularly load bank testing, are often labor-intensive, risk-prone and time-consuming, frequently extending commissioning timelines by several weeks per phase.

faces mounting pressure to deliver facilities faster, safer and with greater reliability. Traditional commissioning methods, particularly load bank testing, are often labor-intensive, risk-prone and time-consuming, frequently extending commissioning timelines by several weeks per phase.

Gaylor Electric’s UL-listed Whip Cart innovation redefines this process. By enabling full-path electrical testing at the server whip level, the Whip Cart not only enhances safety and quality assurance but also compresses the commissioning timeline of a 6MW data hall from weeks to mere days. There are operational, technical and strategic advantages to this breakthrough solution.

THE URGENCY OF SPEED AND PRECISION IN DATA CENTER DELIVERY

Right results matter. Period. The digital economy depends on data centers. From AI and cloud computing to streaming and remote work, the demand for scalable, resilient infrastructure is surging. As data halls grow in complexity and capacity, commissioning becomes a critical bottleneck.

Commissioning ensures that all systems—from power distribution to cooling—are fully operational before a facility goes live. However, traditional commissioning methods often fall short in both speed and completeness, delaying project delivery and increasing risk.

THE CHALLENGE: LIMITATIONS OF TRADITIONAL LOAD BANK TESTING

Load bank testing is essential for simulating real-world electrical loads during commissioning. However, conventional methods typically connect load banks directly to electrical panels or busways, bypassing critical downstream components such as cords, plugs and metering devices. This approach introduces several key limitations:

- Incomplete Testing: Fails to validate and stress-test the full electrical path, leaving potential issues undetected.

- Safety Risks: Requires operating on open and energized panels, increasing the risk of arc flash incidents.

- Labor-Intensive: Demands extensive manpower and procedural overhead, including Method of Procedure documentation.

- Extended Timelines: Sequential testing of components and systems can stretch commissioning over several weeks, especially when complex MOPs require time-consuming setup changes.

- Reliance on Rental Equipment: Load bank testing often involves sequences that can last up to eight hours. Any interruption to this process by equipment failure necessitates a restart of the testing, thereby wasting valuable time.

THE SOLUTION: WHIP CART TECHNOLOGY

THE SOLUTION: WHIP CART TECHNOLOGY

Developed in-house by Gaylor Electric, the Whip Cart is a mobile, field-deployable system engineered to streamline and enhance load bank testing. Unlike traditional methods, the Whip Cart connects directly to the server whips the same cords that will power the servers in production.1

KEY CAPABILITIES:

- Full-Path Testing: Validates the entire electrical path from panel to plug, including cords, plugs and metering devices.

- Plug-Level Connection: Eliminates the need to access live panels, significantly reducing safety risks.

- Mobility and Modularity: Easily repositioned to support rapid, parallel testing across multiple circuits.

QUANTIFIABLE IMPACT: FROM WEEKS TO DAYS

The Whip Cart’s most transformative benefit is its ability to compress commissioning timelines. By

enabling simultaneous Level 3 and Level 4 testing—which are traditionally performed sequentially—the Whip Cart:

- Reduces handoffs between teams

- Minimizes setup and teardown time

- Accelerates issue detection and resolution

- Facilitates server rack installation in parallel with commissioning

In a recent project for an Edged data center, Gaylor Electric demonstrated exactly that. A data hall with 6MW of critical power normally requiring three to six weeks to fully test was validated in just two days.

HERE’S WHAT WAS INVOLVED:

- (48) 400-amp power panels, each feeding 22 individually metered server whips

- (48) 400-amp circuit breakers

- (24) 800-amp automatic transfer switches

- (2) massive 3,000-amp reserve busways

Every circuit was individually metered, stress-tested and verified with infrared scanning and meter validation.

The result? A complete, high-fidelity commissioning process done in a fraction of the time, with full documentation to back it up.

FIELD-PROVEN BENEFITS

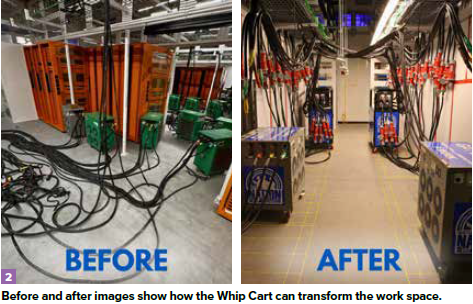

- Enhanced Safety: Arc flash exposure is eliminated by avoiding live panel access, and cords are kept elevated and organized to reduce trip hazards.2

- Operational Efficiency: No MOPs are required for panel access, which streamlines the process significantly. This approach reduces both labor hours and the number of personnel needed for the job. Additionally, the system allows for rapid deployment and easy repositioning across various test zones.

- Superior Quality Assurance: Integrated infrared scanning detects hot spots and faulty connections in real time, enabling proactive issue resolution that reduces rework and delays.

- Comprehensive Validation: This process confirms the performance of metering devices and downstream infrastructure at maximum rated load, providing a more accurate representation of real-world operating conditions.

STRATEGIC ADVANTAGE: COMPETITIVE DIFFERENTIATION

In a competitive market, the ability to deliver faster, safer and more reliable commissioning is a clear differentiator. The Whip Cart positions Gaylor Electric as a leader in innovation, offering clients faster time to market, reduced risk exposure and higher confidence in system performance.

LOOKING AHEAD: SCALING THE INNOVATION

The Whip Cart is an established component of Gaylor Electric’s commissioning strategy. By owning and operating our own fleet of whip carts, load banks, load cables, communications and control systems, Gaylor Electric ensures unmatched quality and control at every stage of the process. This unique capability empowers our teams to consistently deliver work of the highest caliber, regardless of project scale or complexity. Future enhancements aim to expand the Whip Cart’s application across more project types and service lines, reinforcing our commitment to continuous improvement and client success.

Reliable Resources. Reliable Outcomes. Reliable Insights. Genuine Care for People. The future of data center commissioning is here exclusively with Gaylor Electric.