Austin D. McClymonds, Ph.D., Construction Technology Integration Engineer, Leonard S. Fiore

Austin D. McClymonds, Ph.D., Construction Technology Integration Engineer, Leonard S. Fiore

In today’s fast-paced construction environment, accuracy and efficiency are more important than ever. Site layout, one of the first and most critical field tasks, has traditionally been a bottleneck requiring specialized surveyors and painstaking coordination. Advances in construction technology have significantly improved this process. Tools like the Topcon LN150 Layout Navigator, when paired with BIM, make layout more efficient, accurate and accessible to trained field staff.

Leonard S. Fiore, a Pennsylvania based builder known for its hands-on approach and deep self performing capabilities, is using this technology to improve productivity and coordination on complex projects. LSF has embraced this technology to shift layout from a specialized task to an integrated field operation, resulting in improved productivity, better coordination and higher quality execution across projects. LSF has established a standardized workflow for managing layout data across all projects, which consists of three key phases:

Leonard S. Fiore, a Pennsylvania based builder known for its hands-on approach and deep self performing capabilities, is using this technology to improve productivity and coordination on complex projects. LSF has embraced this technology to shift layout from a specialized task to an integrated field operation, resulting in improved productivity, better coordination and higher quality execution across projects. LSF has established a standardized workflow for managing layout data across all projects, which consists of three key phases:

- Model Preparation: Gathering and developing layout-specific files tailored to project requirements.

- Field Implementation: Executing layout activities using the LN150, supported by coordinated oversight.

- Post-Construction: Compiling and documenting as-built data to support facility management and future construction projects.1

MODEL PREPARATION: PRECISION FROM THE START

Accurate and precise model preparation serves as a vital foundation for creating layout files in the field. However, the method of model preparation is influenced by the project’s scope and the specific needs of the project team.

To ensure the model aligns with these requirements, clear communication between the on-site project team and LSF’s construction technology department is crucial. This teamwork guarantees that the model assists in successful layout execution.

No matter the complexity of the project, a few essential details are always needed for a successful layout: established control points, geolocated gridlines and a CAD file that outlines the elements required for layout.

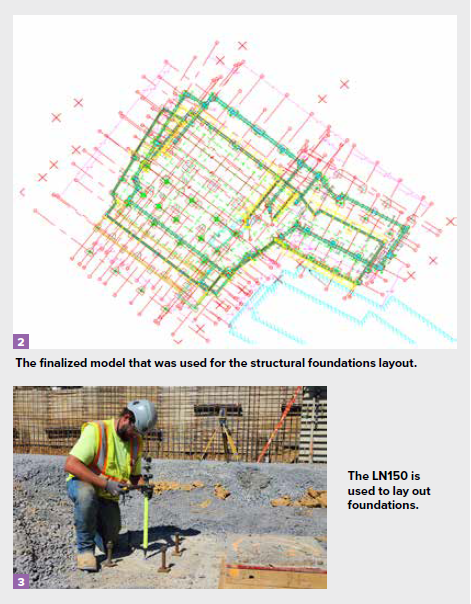

All data used to develop the layout model must be thoroughly verified against the “for construction” contract documents to ensure accuracy and readiness for field use. To illustrate this process, let us take a closer look at model preparation for one of our ongoing projects at Penn State’s main campus: the New Classroom Building. LSF’s scope of work includes the concrete package. To lay out the structural foundations, three models were developed:

- Base Model: Contains site geometry, gridlines and control points.

- Foundation Model: Depicts the locations of all pile caps, piles, grade beams and walls.

Concrete Form Model: Shows the exact locations of the concrete formwork used for walls. These models are carefully aligned and georeferenced to ensure consistency. Additionally, they are formatted as DWG files, where model layers and linework are simplified to reduce confusion for the LN150 operator.

Once verified for accuracy, the models are uploaded to an LN150 data collector and reviewed. Each model is loaded into the project separately to provide the operator ability to toggle each model on or off. This functionality enables the field team to confirm that the correct linework is selected for the task.2

FIELD IMPLEMENTATION: LAYOUT WITH QUALITY ASSURED

Once the models are verified for quality, a coordination meeting is held with the LN150 operator, the construction technology department and the site superintendent. The purpose of this meeting is to review the layout model, confirm it meets or exceeds project expectations and ensure it is ready for field use.

After the review, the finalized models are loaded onto the LN150 data collector. The operator then takes time to familiarize themselves with the model—reviewing the linework, layer structure and layout intent—allowing them to ask questions or request clarification before work begins.

Upon arrival on site, the first step is to locate the control points established by a third-party surveyor. These points serve as the foundation for all layout activities. Using two control points, the LN150 is set up and calibrated. During setup, the instrument displays an accuracy reading, which must meet the project tolerance requirement (typically 1/16” or better). Once the setup and accuracy are confirmed, the layout process for the structural foundations begins.

To maintain quality throughout the layout process, several steps are followed. First, all laid-out lines are visually inspected to ensure they align with field conditions and construction intent. As the saying goes, “If it doesn’t look right, it probably isn’t.” In addition, the operator frequently verifies dimensions using a tape measure, cross-checking against both the model and the contract documents. In addition, the LN150 enhances jobsite quality by enabling real-time verification of critical layout elements such as wall lines, anchor bolts, formwork and elevations. This ensures that all model components are installed in their correct locations, reducing rework and improving overall accuracy.

Finally, points laid out are recorded as an as-built shot, capturing their coordinates (northing, easting and elevation). This data allows for post- layout verification and provides a record of the field layout. As-built data is consistently collected and stored for all major layout activities performed with the LN150, including—but not limited to— foundations, walls and site utilities.3

POST-CONSTRUCTION: CAPTURING THE FINAL PRODUCT

Once the layout is complete, as-built data is verified and turned into a final documentation package: annotated plans, georeferenced CAD files and field notes. This data does not just close out a job; it opens the door to better facility management and future work.

Owners benefit from a reliable, digital snapshot that reflects as-built conditions, reducing future rework and giving teams a solid starting point for renovations or expansions. In this way, the as built data extends the value of the layout process beyond construction.

By leveraging BIM and tools like the LN150, LSF is not only delivering precision in the field, but also building confidence with owners, architects and trade partners. Standardizing layout workflows improves safety, accountability and project delivery.